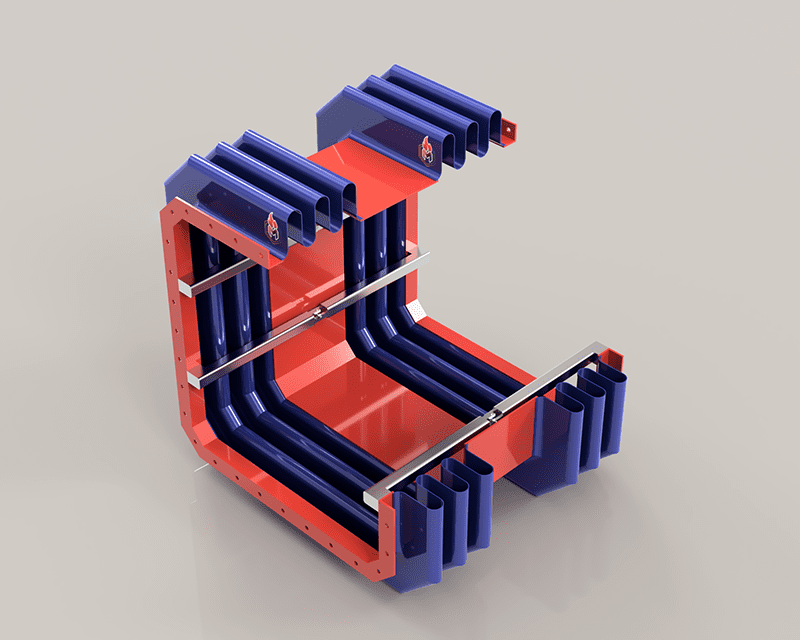

SINGLE LAYER METAL EXPANSION JOINTS

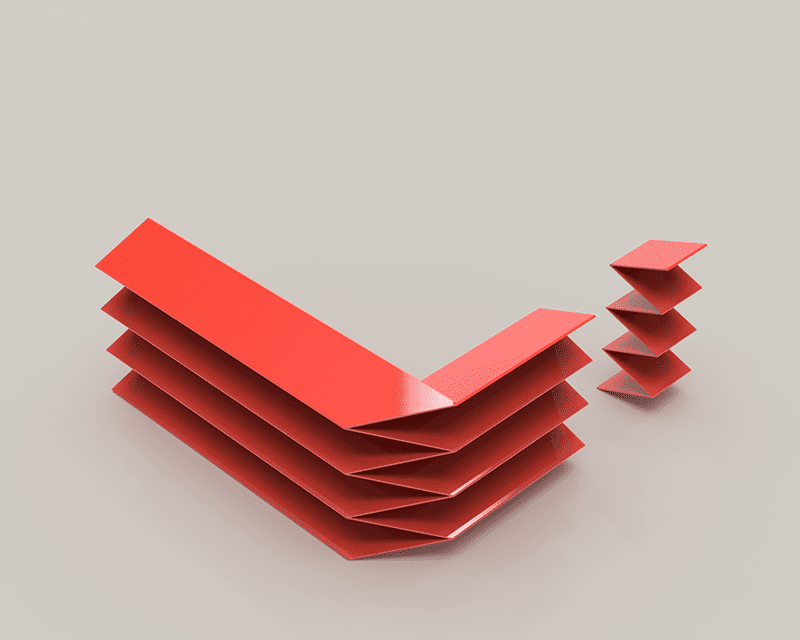

Single-layer metal compensators are single-walled metal compensators with a very robust construction, available in single or multi-knuckle variations.

Metal corrugations are obtained by welding one or several parts together according to the dimensions of the compensator.

Polygonal and rectangular carcasses can be manufactured in U-profile, V-profile and Rectangular profiles, while Circular carcasses are manufactured only from U-profiles.

Circular corrugations can be manufactured by welding two halves at the apex or by bending from one piece, depending on the pitch height.

It can absorb high axial movements and thanks to its wide corrugations, the risk of clogging in particulate fluids is less than other metal compensators.

Filling the corrugation gaps of the expansion joints operating in high temperature lines with insulating material delays the fatigue of the steel and helps the compensator to provide long-lasting performance.

Advantages of Single Layer Metal Expansion Joints

- Internal insulation possible

- Low application area requirement

- High corrosion and wear resistance

- Possibility of patching the worn areas with welding

- High performance in fluids with solid particles

- Ease of manufacture and low cost in large scales

- Drainage pipe application against the risk of acidic condensation

Nominal diameter: DN300 - DN12000

Pressure class: PN1 - PN100

Nominal diameter: DN100 - DN12000

Basınç sınıfı: PN1 - PN60

Inner dimensions: Max. 12000x12000 mm

Pressure class: PN1 - PN80

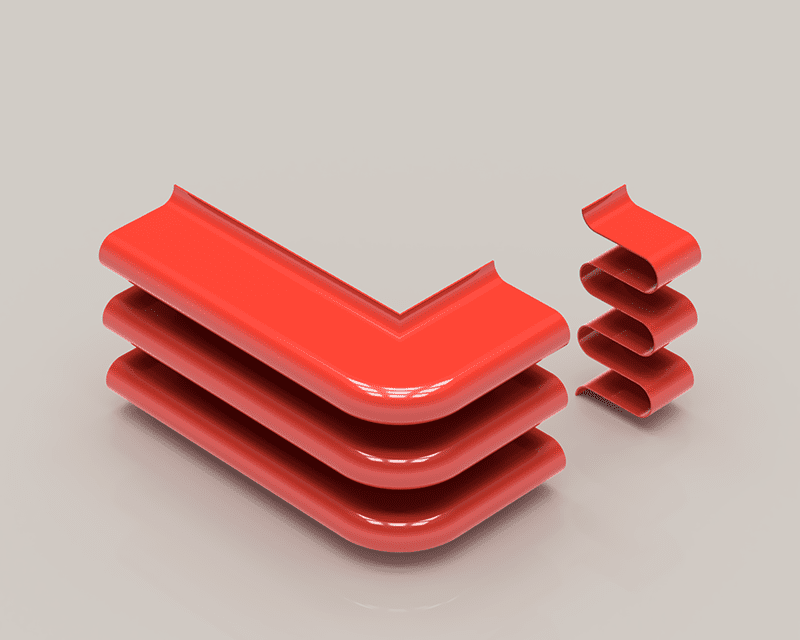

Single Miter

Single Miter

This is the most common and economical type used to compensate for thermal expansion. It is preferred in low-speed and vibration-free applications.

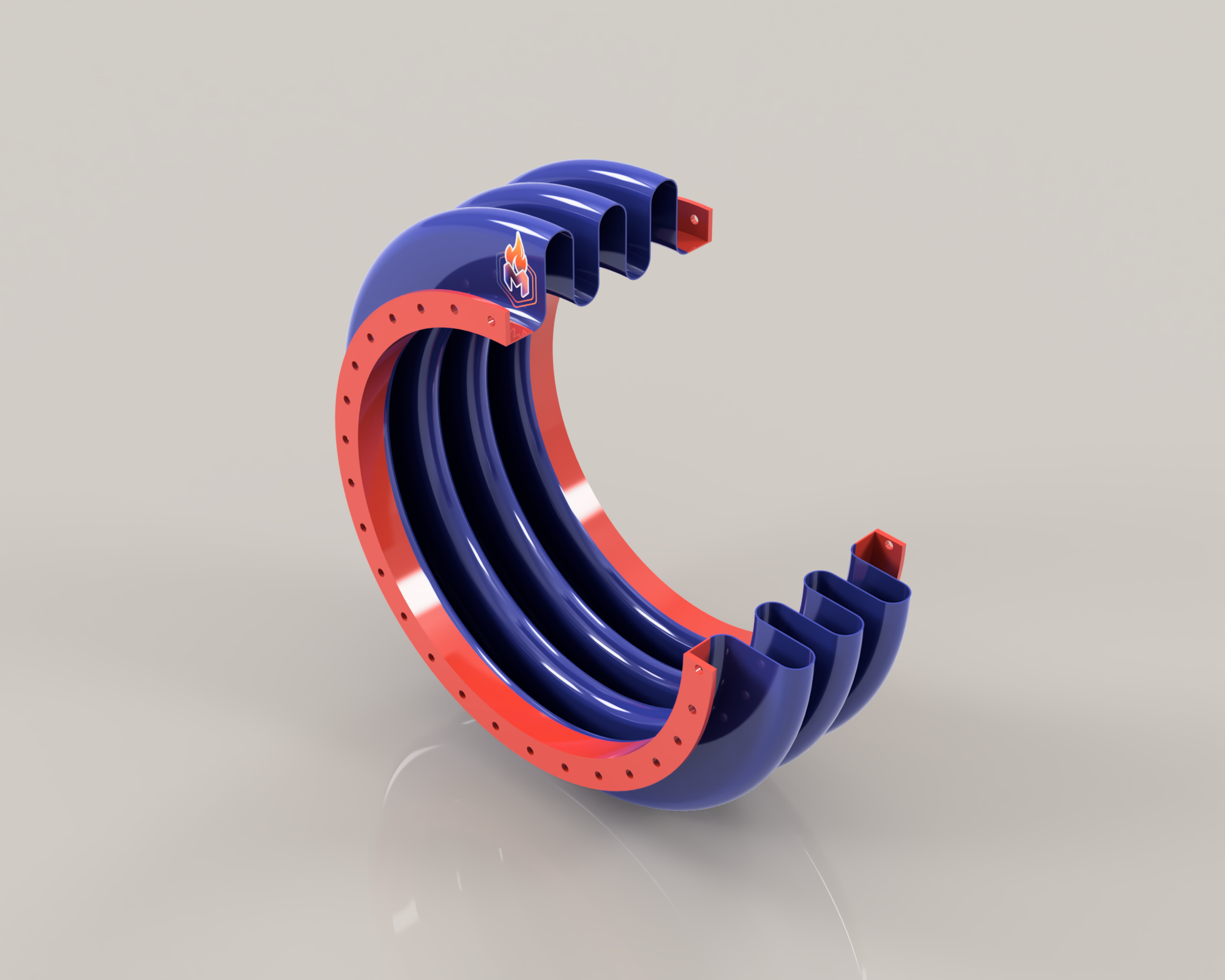

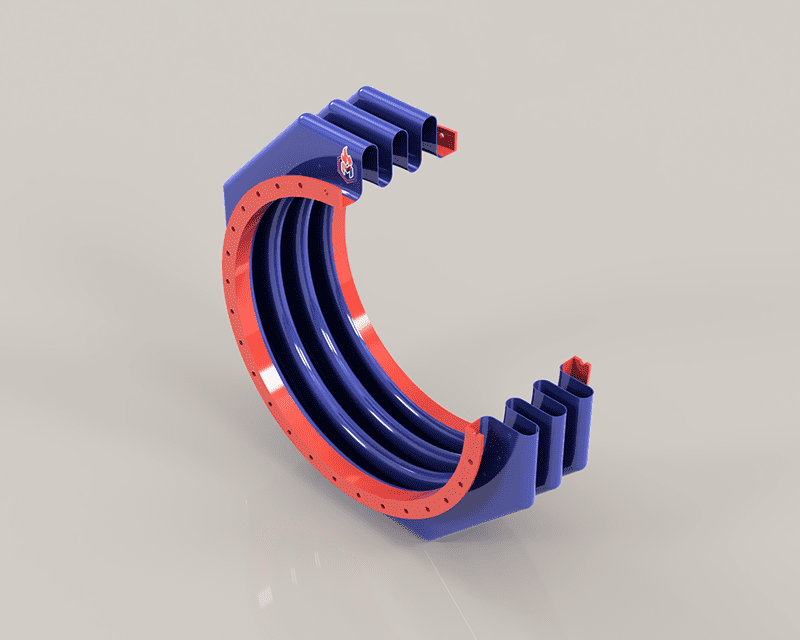

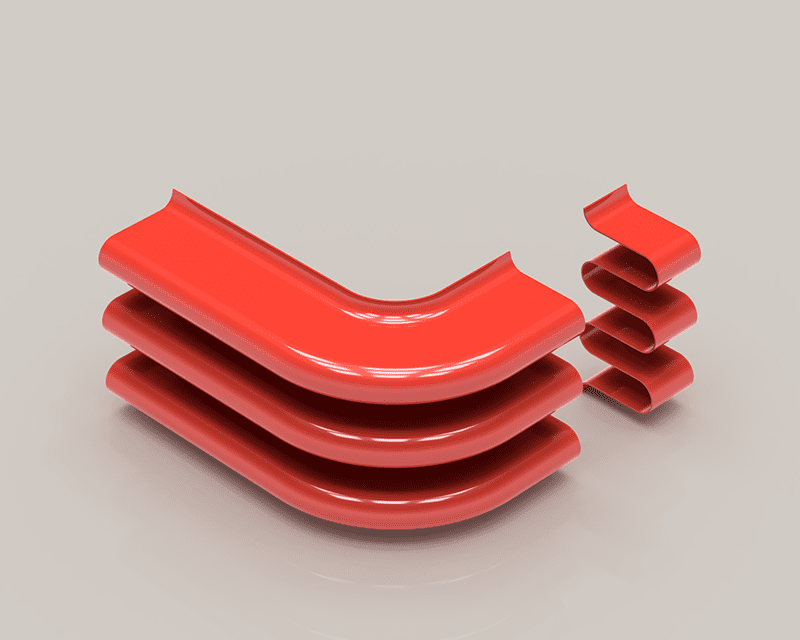

Round

Round

This type is used in applications where vibration and cycle life are important factors. Round corners are the most expensive to manufacture, but have the advantage of reducing corner stress.

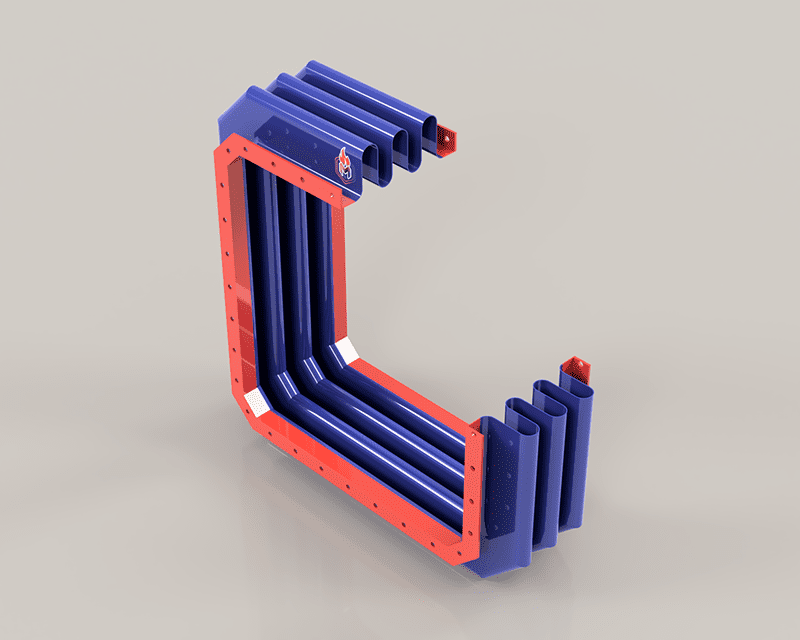

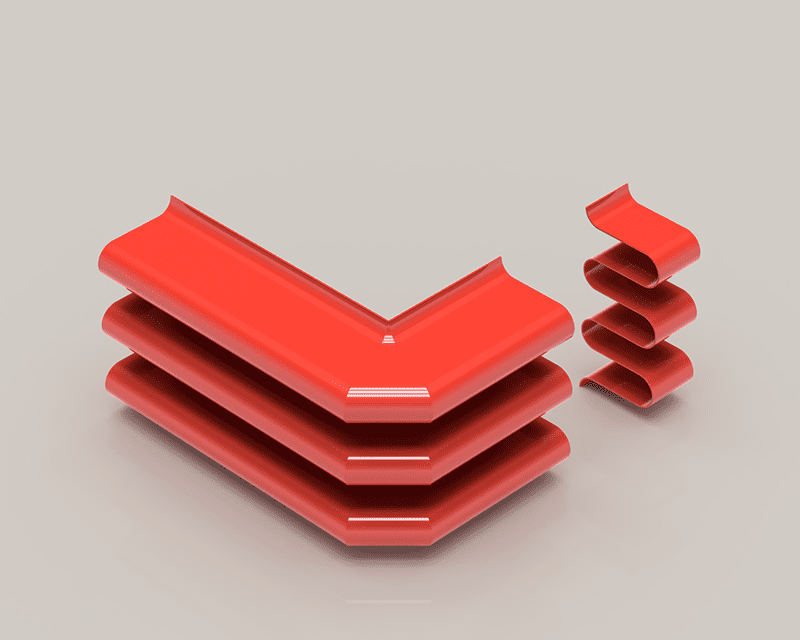

Double Miter

Double Miter

This type costs slightly more to manufacture than the single-angle corner design, but offers a longer lifetime under the same operating conditions.

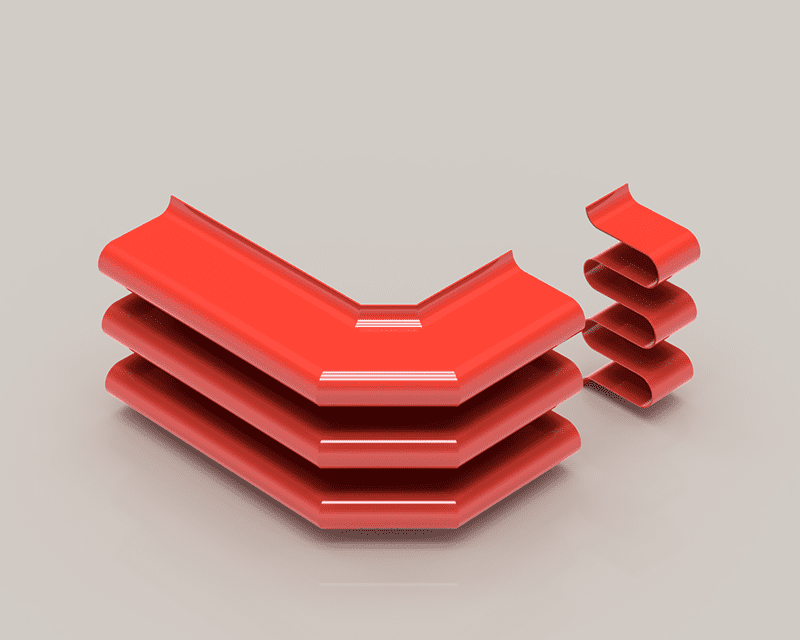

Full Round

Full Round

Since its inner and outer corners are rounded, it offers much better performance than the previous corner design.

Full Double Miter/span>

Full Double Miter/span>

Since its inner and outer corners are double angled, it offers much better performance than the previous corner design.

Camera

Camera

This type is mainly used in low pressure applications. They have good cycle life characteristics and cost less than the double angle corner design. It has the disadvantage of reduced motion, as the contours of the camera corners overlap in the corner. It is suitable for V-profile use only.

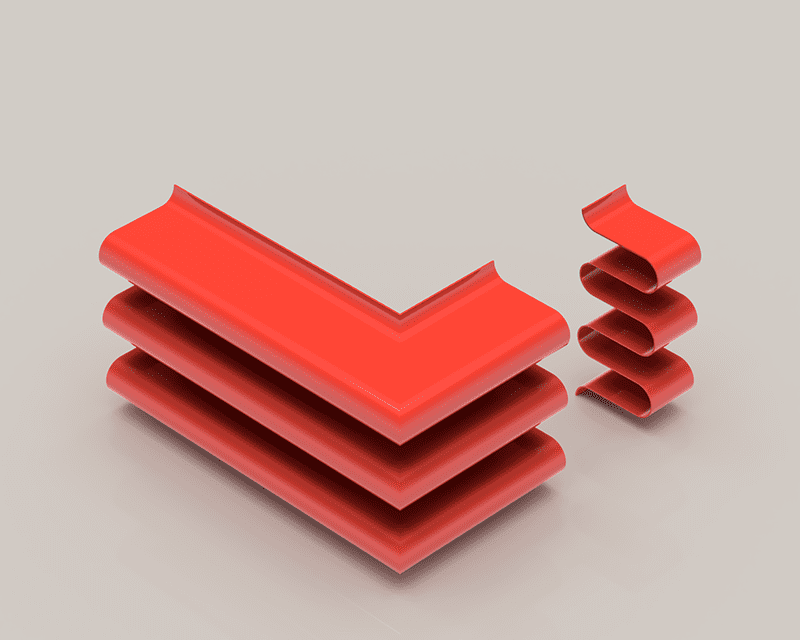

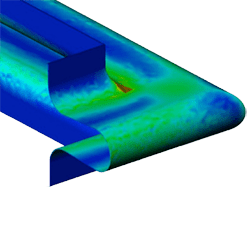

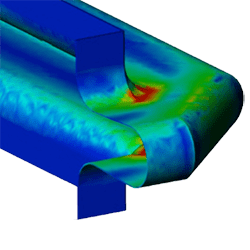

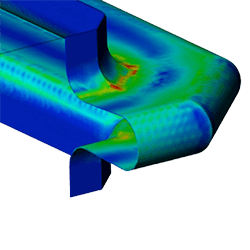

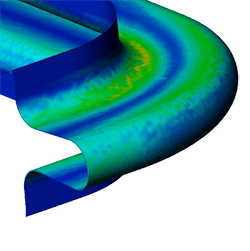

The results of SEM (Finite Element Method) analysis on the right show the stress distribution (Von Mises) of 4 different corner types in the U-Type profile under the same load.

The decreasing stress map from red to blue shows that the stress intensity is more evenly spread with decreasing corner angles in the compensator.

Considering these data in the design of the compensator plays an important role in providing longer lasting performance of the compensator.

Tek Açılı

Çift Açılı

Tam Çift Açılı

Tam Yuvarlak

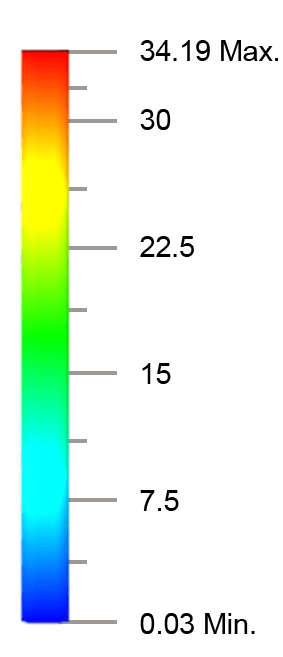

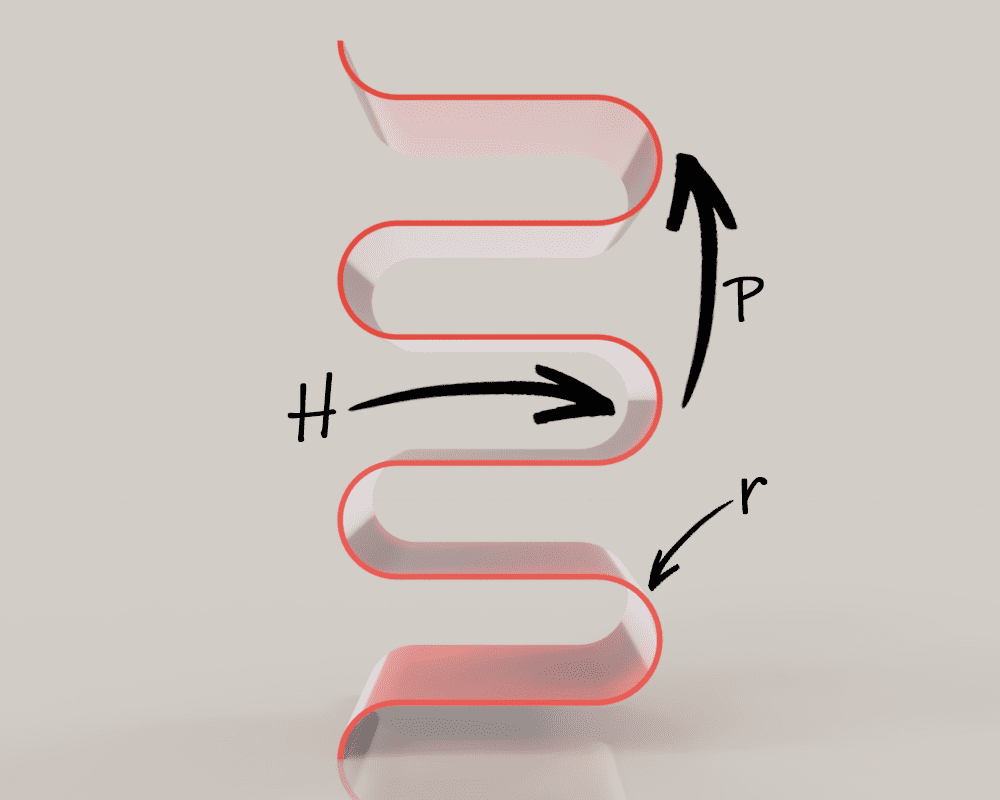

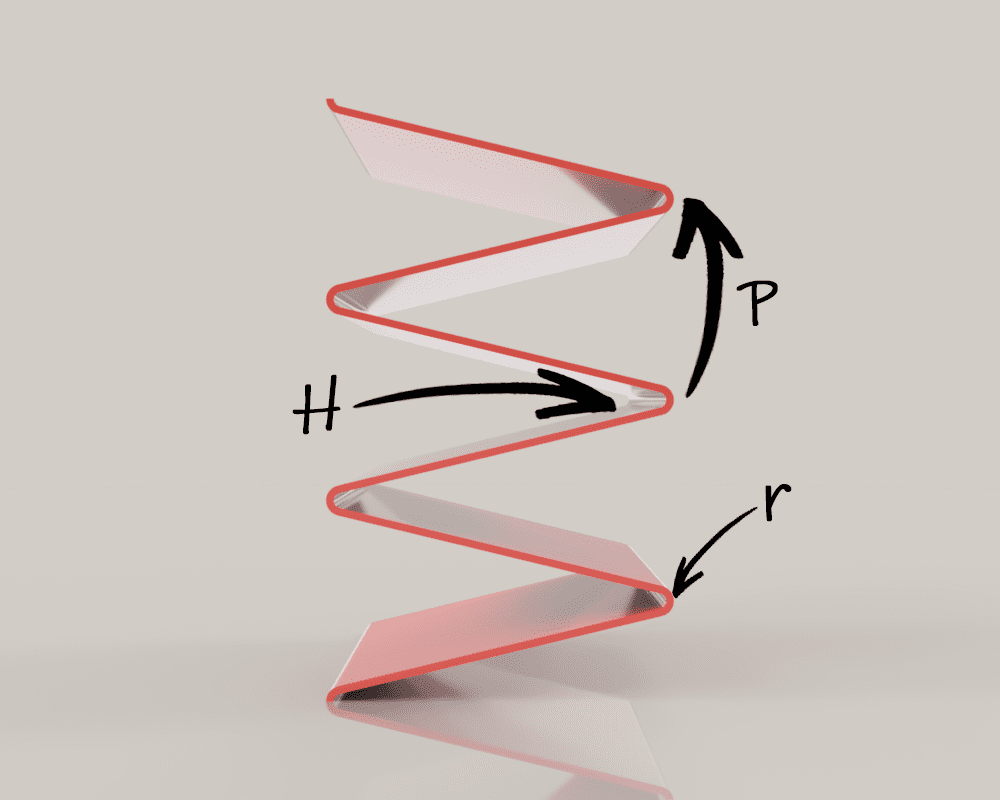

Min. Radius (r)=

15mm (t=1,5mm)

30mm (t=2-3mm)

60mm (t=4-5mm)

Peak Distance (P)=r*4

Convolution Depth (H)=80~200mm

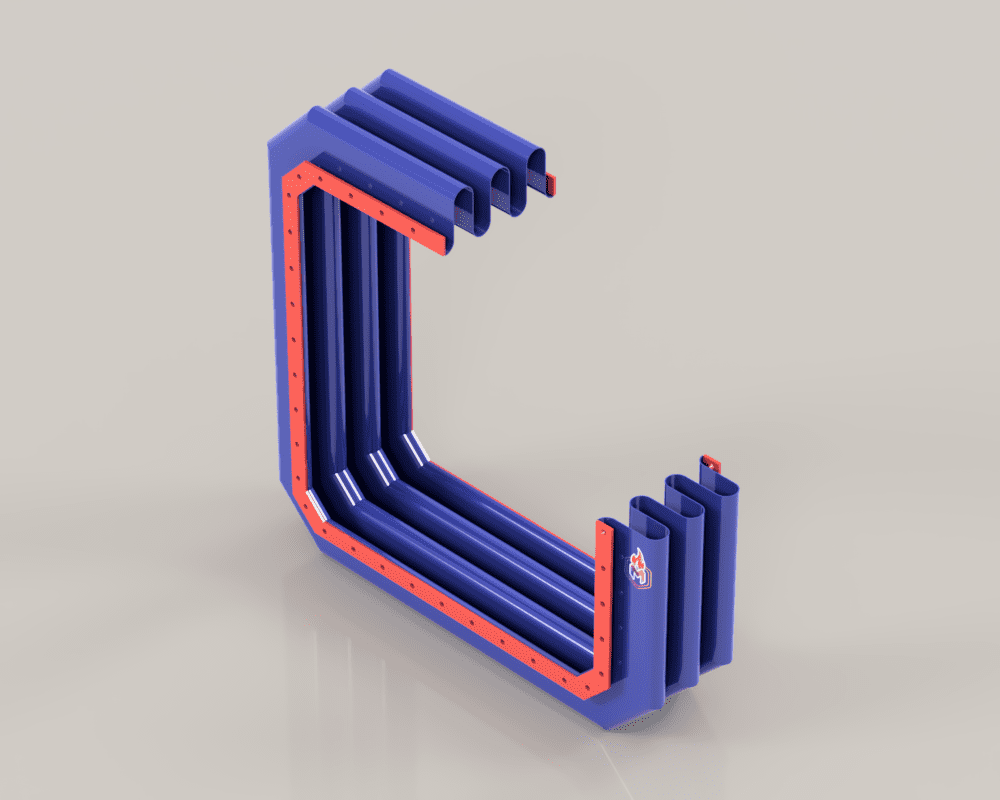

Circular, Polygonal, Rectangular frame options

Min. Radius (r)=t*2

Peak Distance (P)=100~250mm

Convolution Depth (H)=100~300mm

Polygonal, Rectangular frame options

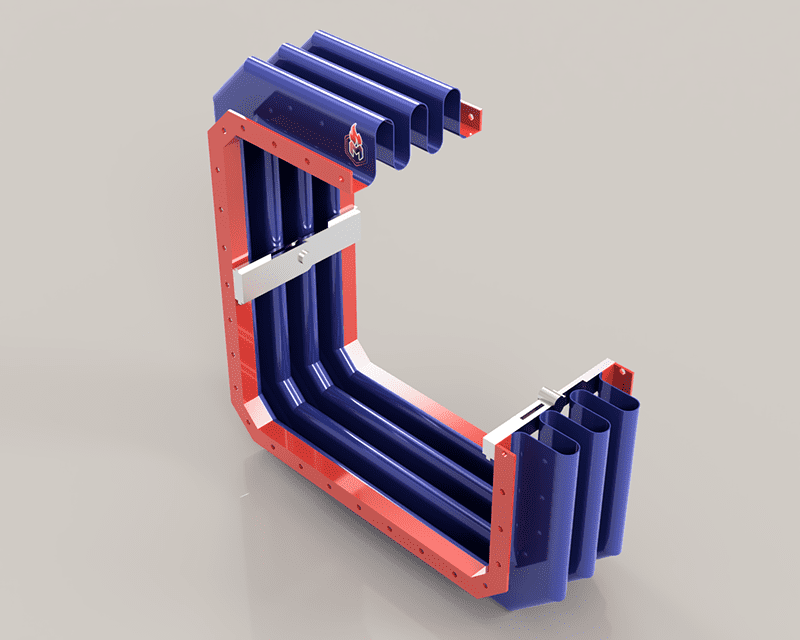

Min. Radius (r)=t*1,5

Peak Distance (P)=100~250mm

Convolution Depth (H)=100~300mm

Polygonal, Rectangular frame options

Axial

Axial

Lateral

Lateral

Angular - Hinged

Angular - Hinged

Angular - Gimbal Hinged

Angular - Gimbal Hinged

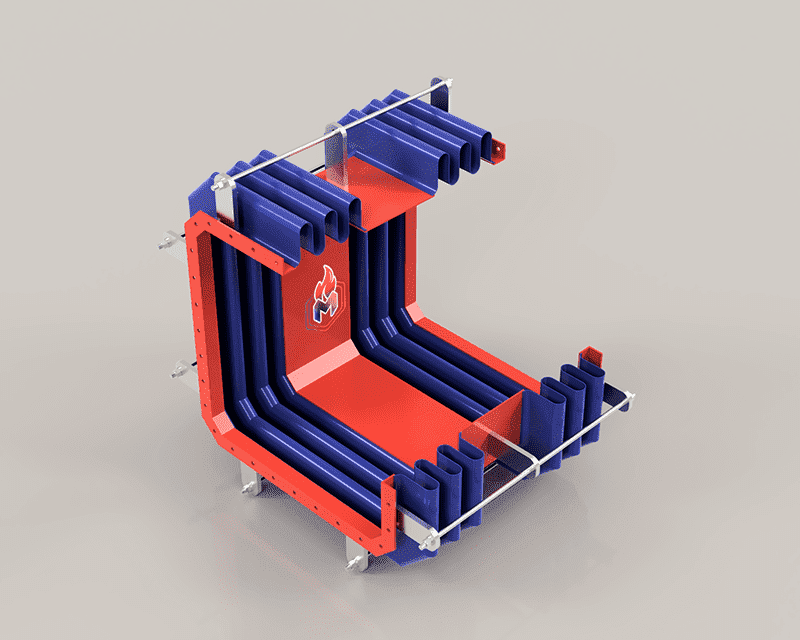

Shell Expansion Joint

If a metal compensator is leaking or damaged or needs to be replaced with minimal downtime, Shell Expansion Joints should be considered as the solution.

Shell compensators manufactured in two halves are assembled on site by our expert, certified welding teams.

Depending on the working conditions, extra protection can be provided by filling the corrugation gaps with insulation material as in the example.

Easy Fix Expansion Joint

These compensators are positioned at a suitable distance for grinding-re-welding operations so that their corrugations can be changed partially or completely.